pattern making with 3d samples

If you want your designs to be produced exactly as you imagined them, then you MUST supply the factory or sample maker with accurate and easy to follow patterns (in addition to tech packs). Even if you already have a working prototype, you should still supply accurate patterns if you want your product to turn out as you’ve envisioned it. In some cases (for very simple designs), a working prototype along with a tech pack may be sufficient BUT, supplying your own patterns is both a fail safe and a way to keep your production partners accountable. It is also an absolute necessity if your designs are more complicated. I recommend ALWAYS providing factories and sample makers with your own patterns. Even if the factory or sample maker say that they don’t need them, I would still recommend supplying your own patterns and insisting that they follow them. I can work with your brand to create accurate patterns. I can create patterns from a physical prototype, specs or an idea.

Factories and sample makers are often working on several projects at the same time. Relying on them to create your samples or production run without supplying them with accurate and easy to follow patterns means leaving things to chance, and thereby creating more room for error.

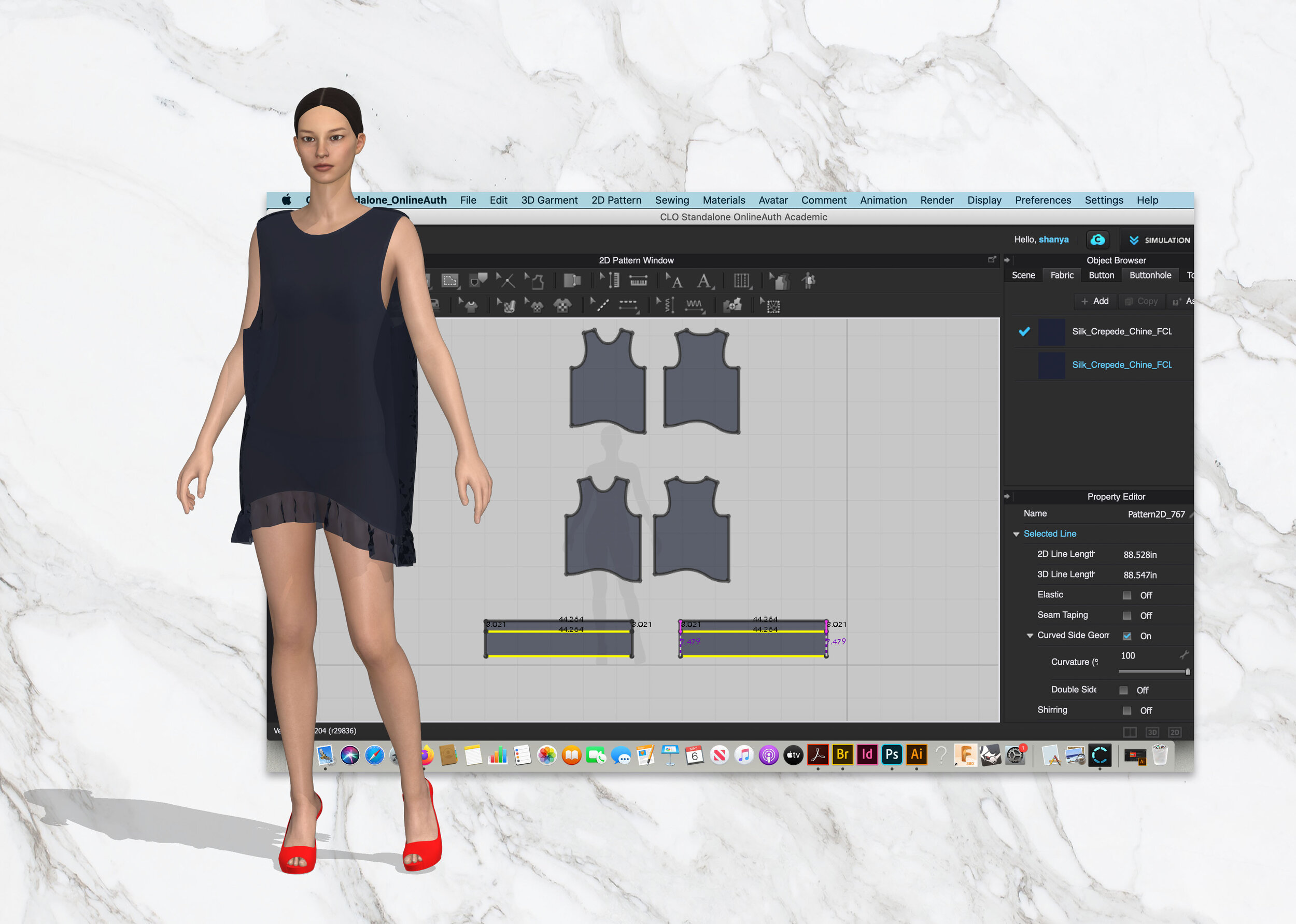

To round out my technical design services, 3D samples serve as a final fail safe tool to test out patterns and tech packs before proceeding to physical sample making and production. Digital 3D samples are used to make sure that everything looks and works properly before the next stages. Utilizing digital 3D samples can save brands precious time and money and limit the stress of things going awry. Scroll down to learn more about the benefits of using 3D samples.

True to life digital 3D samples can be used as a fail safe during the technical design phase to make sure everything checks out before spending time and money on physical samples.

Utilizing 3D design and development assets can speed up production, cut costs, improve sustainability by reducing waste and enhance a brand’s e-commerce presence. I utilize the latest 3D fashion design technology to showcase design renderings and deliver accurate patterns that can be easily and effectively employed by any of your production partners. I can develop and easily format patterns to any of your designated contractors’ specifications. Scroll down to learn more about the benefits of utilizing 3D Design and development technology.

Rapid 3D simulation can instantly close the gap between sketch and prototyping, turning an uncertain wait time (weeks or even months under current conditions) into a matter of hours. 3D simulation, also makes it easier for Designers to experiment at any phase in the process prior to production.

True to life 3D simulations allow you to get to market faster by receiving early feedback and making faster decisions, before creating the first physical prototype

Create quick and easy true to life colorway variations to see what works in each silhouette.

Quickly experiment with design details and silhouette variations.

By utilizing 3D assets, brands can reduce production costs that are associated with numerous samples and fittings. 3D Technology can also provide an accurate estimate of the material consumption required for each silhouette, allowing brands to plan and budget more effectively, while getting ahead of any financial setbacks that may impact their designs and delay production.

Maximize accuracy by utilizing 3D technology to first fine tune details of your garment before moving to a physical sample. The changes made to the 3D sample directly affect the 2D pattern and physical sample.

Get immediate and accurate feedback of the costs associated with each design change.

Create virtual samples in various sizes using advanced grading tools that allow you to easily and simultaneously grade your patterns and at the same time visualize an accurate draped result in 3D.

3D assets can provide accurate, true to life representations of what a product or garment looks like. This can significantly reduce the number of samples that are required during the development process. Not only does the option of virtual pattern editing and 3D simulated samples reduce production costs, it can also have a profound effect on waste.

Often several rounds of development samples are required to achieve the perfect look and fit. Utilizing true to life virtual samples to first fine tune design details before moving to physical samples will reduce waste and improve a brand’s sustainability initiatives.